Foil stamping is something special. It is a balance of heat, foil, paper, pressure, magnesium, and accuracy. It is a science as much as an art. We field many questions regarding the foil stamping process. So, we thought it would be fun to give a little insight into what our foil stamping process looks like. At Locust Street Press, we run our foil stamping process on 60+ year old Kluge presses.

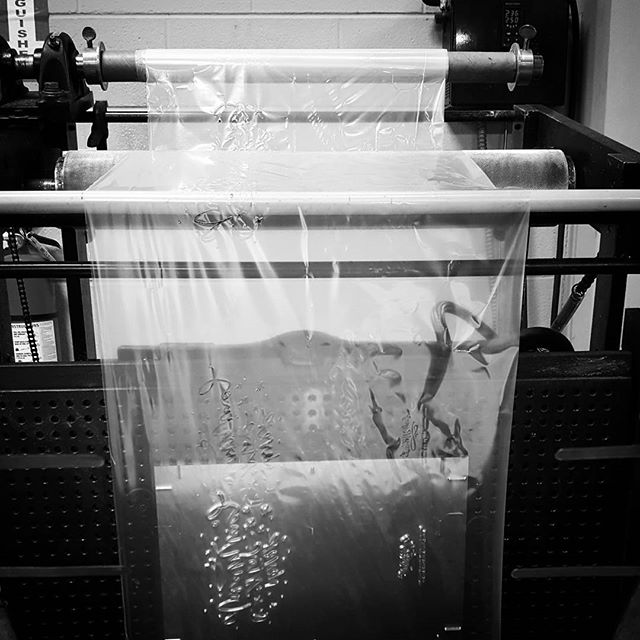

The process is an intricate interweaving of foil material through a series of rollers. The pegboard type plate there heats to temperatures in excess of one hundred degrees. This temperature combined with the pressure of the closed press, squishes the foil material between a magnesium plate (of your design) and the paper. The heat and pressure combine to leave the paper with your pretty foil details.

I assure you this is a simple understanding of the process. There are countless other elements to ensure that a foil design is exactly where it is meant to be. The foil stamping process is completely done by hand. Our old presses were manufactured, back in the day, with their own integrated tool boxes and for good reason. It is rather unbelievable: the amount of effort it is to mount a roll of foil and a magnesium die, let alone correctly align the paper.

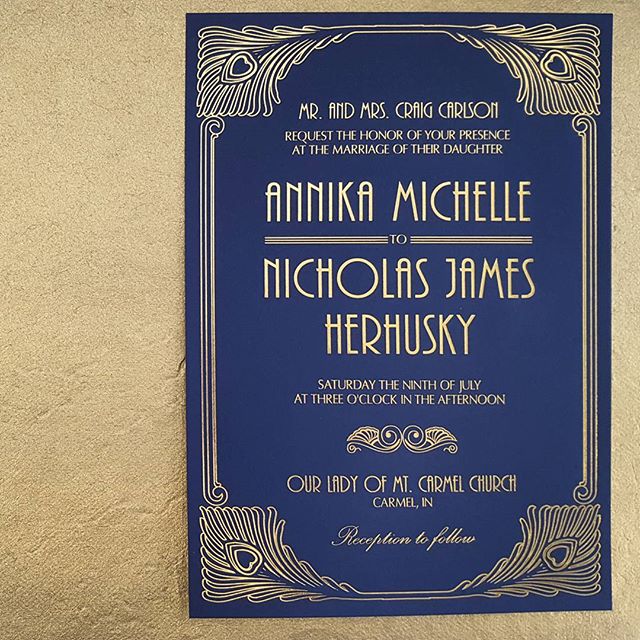

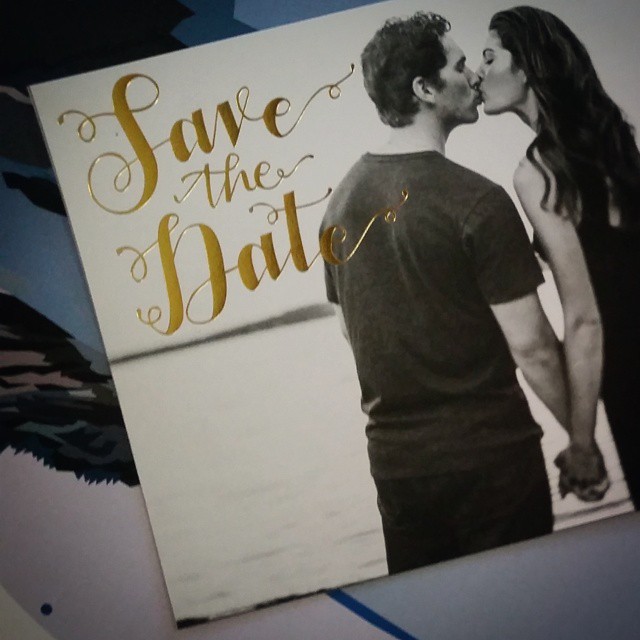

We love our old presses, old ways, and pretty foils. We hope that by sharing our process it gives you a better understanding of the worth innate in handmade. It is hard work, but boy is it pretty!